Automotive Test List

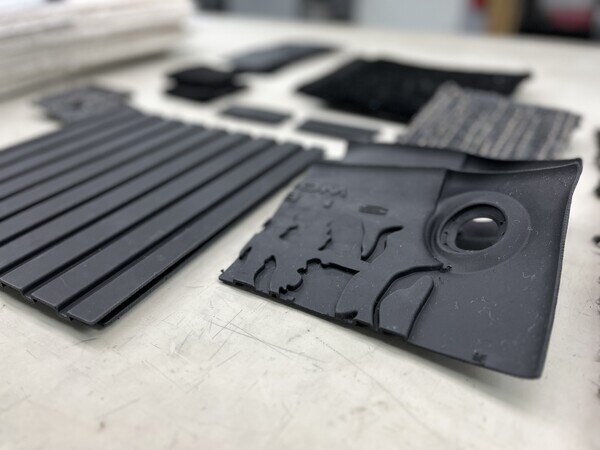

Professional Testing Laboratory provides comprehensive testing on automotive interior fabrics, upholstery, rubber floor mats, carpets, and other automotive materials from foams and dash components to insulation.

Explore our full test list below or contact us today for a quote with a quick turnaround on testing for automotive materials and parts such as:

- Interior flooring

- Bumpers

- Dashboards

Don’t see the test you need? We also offer custom automotive testing services to suit the unique needs of your automotive product or component. Let us know the details and we’ll get you the data.

| Test Name | Category |

|---|---|

| 87000 ND500 Section 5-19: Antistatic Performance | Automotive, |

| AATCC 16 Colorfastness to Light (Xenon Arc) 40 AFU | Automotive, |

| AATCC 165 Colorfastness to Crocking | Automotive, |

| AATCC 8 Colorfastness to Crocking | Automotive, |

| Absorbency By Volume | Automotive, |

| Accelerated Aging by Oven (per day) | Automotive, |

| Accelerated Life Exposure Dimensional Change | Automotive, |

| AS 2001.4.21 Colorfastness to Light using Mercury Vapour Tungsten Filament, internally Phosphor Coated Lamp | Automotive, |

| Asbestos | Automotive, |

| ASTM B117 Salt Spray depends on size and length of time duration | Automotive, |

| ASTM C1313 Adhesive Performance | Automotive, |

| ASTM C1313 Pliability | Automotive, |

| ASTM C1378 Standard Test Method for Determination of Resistance to Staining | Automotive, |

| ASTM D1004 Tearing Strength | Automotive, |

| ASTM D1056 Low Temperature Flex Test | Automotive, |

| ASTM D1335 Tuft Bind | Automotive, |

| ASTM D1335 Tuft Bind (Wet) | Automotive, |

| ASTM D1335 Tuft Bind with Infill | Automotive, |

| ASTM D1790/D2136 Low Temperature (Impact/Bend/Roller) | Automotive, |

| ASTM D1894 Coefficients of Friction of Plastic Sheeting | Automotive, |

| ASTM D1929 Determining Ignition Temperature of Plastics | Automotive, |

| ASTM D2097 Flex Resistance Test | Automotive, |

| ASTM D2240 Hardness Shore A Durometer | Automotive, |

| ASTM D2240 Hardness Shore A Durometer (Oil Exposed) | Automotive, |

| ASTM D2257 Extractable Matter in Textiles | Automotive, |

| ASTM D2261 Tearing Strength | Automotive, |

| ASTM D2582 Puncture Resistance | Automotive, |

| ASTM D2646 Breaking Load & Elongation | Automotive, |

| ASTM D2646 Shrinkage Hot-Dry Conditions | Automotive, |

| ASTM D2646 Shrinkage Hot-Wet Conditions | Automotive, |

| ASTM D2646 Tensile Strength | Automotive, |

| ASTM D2710 Specific Gravity | Automotive, |

| ASTM D297 Ash Content | Automotive, |

| ASTM D3273 Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber | Automotive, |

| ASTM D3389 Taber Abrasion DHRP (up to 5,000 cycles) | Automotive, |

| ASTM D3511 Pilling Resistance | Automotive, |

| ASTM D3597/D4157 Wyzenbeck Abrasion (15,000) | Automotive, |

| ASTM D3776 Total Weight | Automotive, |

| ASTM D3786/D3787 Bursting Strength | Automotive, |

| ASTM D3884 Abrasion Resistance 5,000 cycles or less SEE CHART FOR MORE CYCLES | Automotive, |

| ASTM D3884 Abrasion Resistance 5,000 cycles or less w/measurement | Automotive, |

| ASTM D3885 Abrasion-Flex (1st 1500 cycles/ea addl 1500) | Automotive, |

| ASTM D3886 Abrasion-Diaphragm (1st 2500 cycles/ea addl 2500) | Automotive, |

| ASTM D3936 (Wet) Delamination Strength of Secondary Backing | Automotive, |

| ASTM D3936 Bond Strength | Automotive, |

| ASTM D3936 Delamination Strength | Automotive, |

| ASTM D3936 Delamination Strength of Secondary Backing | Automotive, |

| ASTM D3936 Delamination Strength of Secondary Backing (Delamination Strength Exceeds Backing Strength) | Automotive, |

| ASTM D395B Compression Set | Automotive, |

| ASTM D4060 Abrasion Resistance w/weight loss (less than 5,000 cycles) see chart | Automotive, |

| ASTM D412 Breaking Load & Elongation | Automotive, |

| ASTM D412 Breaking Load & Elongation (Oil Exposed) | Automotive, |

| ASTM D412 Breaking Load & Elongation (Top, Middle, Bottom) | Automotive, |

| ASTM D412 Breaking Load & Elongation w/Modulus | Automotive, |

| ASTM D413 Adhesion Test | Automotive, |

| ASTM D4157 Abrasion Resistance - Wyzenbeek (additional 10,000 cycles) | Automotive, |

| ASTM D4157 Abrasion Resistance - Wyzenbeek (up to 10,000 cycles) | Automotive, |

| ASTM D434/D4034 Seam Slippage, Apparel/Upholstery | Automotive, |

| ASTM D4533 Tearing Strength - Trapezoid Procedure | Automotive, |

| ASTM D4632 Breaking Strength and Elongation | Automotive, |

| ASTM D471 Effects of Liquids on Rubber Properties | Automotive, |

| ASTM D5040 Ash Content | Automotive, |

| ASTM D5116 Modified Organic Emissions Testing | Automotive, |

| ASTM D5420 Gardner Impact | Automotive, |

| ASTM D543 Resistance to Plastics to Chemicals | Automotive, |

| ASTM D5582 Standard Test Method for Determining Formaldehyde Levels from Wood Products Using a Desiccator | Automotive, |

| ASTM D5587 Tearing Strength | Automotive, |

| ASTM D570 Standard Test Method for Water Absorption of Plastics | Automotive, |

| ASTM D570-98 Water Absorption | Automotive, |

| ASTM D5735 Tearing Strength Tongue Procedure | Automotive, |

| ASTM D737 Standard Test Method for Air Permeability of Textile Fabrics | Automotive, |

| ASTM D7596 Xenon Arc Exposure with Enhanced Light and Water Exposure for Transportation Coatings | Automotive, |

| ASTM D790 Flexural Strength | Automotive, |

| ASTM D792 Specific Gravity | Automotive, |

| ASTM E1252 Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis | Automotive, |

| ASTM E1333 Standard Test Method for Determining Formaldehyde Concentrations in Air and Emission Rates from Wood Products Using a Large Chamber | Automotive, |

| ASTM E1349 Standard Method for Reflectance Factor Using 45 degree/0 degree Geometry | Automotive, |

| ASTM E96 Water Vapor Transmission (one side) | Automotive, |

| ASTM F150 (IBM/Burroughs / NFPA 99) | Automotive, |

| ASTM F2765 CPSC Lead Analysis | Automotive, |

| ASTM F2853 Determination of Lead in Paint Layers and Similar Coatings by X-Ray Fluorescence | Automotive, |

| BMW 3.2.10 Imprint Behavior Without Foam Impression Depth @ 60 Minutes and 24 hours (DIN 54316/EN20 105 A02) | Automotive, |

| BMW 3.2.10.2 Tested at 60 degrees C, Impression Depth at 60 minutes and 24 hours | Automotive, |

| BMW 3.2.10.3 Tested Wet after 50 Minute Soak, Impression Depth at 60 minutes and 24 hours | Automotive, |

| BMW 3.2.3.2 Total Thickness | Automotive, |

| BMW 3.2.4.1 Total Weight per Unit Area | Automotive, |

| BMW 3.2.4.2 Pile Yarn Thickness | Automotive, |

| BMW 3.2.4.3 Pile Weight | Automotive, |

| BMW 3.2.6 Gauge | Automotive, |

| BMW 3.2.7 Number of Tufts | Automotive, |

| BMW 3.3.1 Abrasion Resistance with Loss of Weight and Change in Color (DIN 53 109 and EN 20 105 A02) | Automotive, |

| BMW 3.3.1 Straight Tensile Strength Original | Automotive, |

| BMW 3.3.1.1 Straight Tensile Strength After Fade | Automotive, |

| BMW 3.3.1.1 Straight Tensile Strength After Heat Aging (7 days) | Automotive, |

| BMW 3.3.2 Colorfastness to Light (1 cycle Blue Wool $40, 2 cycles Gray Scale $80, 3 cycles Gray Scale $80) (ISO 105 B06) | Automotive, |

| BMW 3.3.3 Colorfastness to Crocking (wet and dry) (ISO 105 X12) | Automotive, |

| BMW 3.3.3 Heat Aging (7 days) | Automotive, |

| BMW 3.3.4 Surface Resistance (DIN 345 T6) | Automotive, |

| BMW 3.3.5 Rotting Resistance (VDA 270) | Automotive, |

| BMW 3.3.6 Odor Test (VDA 270) | Automotive, |

| BMW 3.3.8 Accelerated Soiling after vacuuming and cleaning (PR121.2) | Automotive, |

| BMW 3.4.1 Resistance to Fade | Automotive, |

| BMW 3.4.1 Thickness | Automotive, |

| BMW 3.4.2 Resistance to Crocking | Automotive, |

| BMW 3.4.3 Resistance to Bleed, Perspiration and Spotting | Automotive, |

| BMW 3.5.1 Total Thickness (ISO 1765) | Automotive, |

| BMW 3.5.2 Total Weight (ISO 8543) | Automotive, |

| BMW 3.5.3 Tensile Strength (ISO 13 934 T1)..3.5.4 Ellongation | Automotive, |

| BMW 3.5.6 Dimensional Stability (ISO 13 934 T1) | Automotive, |

| BMW 3.6 Print Adhesion | Automotive, |

| BMW 3.7 Setting Time for Normal Handling, Storage Stability | Automotive, |

| BMW 3.9 General Acceptance Criteria | Automotive, |

| BMW 6951 680.6 Dimensional Stability | Automotive, |

| BMW Automotive Battery BMW 7 145 612.6 Tufted Carpet Specification | Automotive, |

| BMW Drag Resistance PR 380:2008-09 2.2.5 Adhesion Force | Automotive, |

| BMW Environmental BMW PR 303:4 | Automotive, |

| BMW Environmental BMW PR 303:4 (Additional Mats) | Automotive, |

| BMW GSA 97014-2 | Automotive, |

| BMW PR 319 Dimensional Stability | Automotive, |

| BMW TL-2 754 531.6 Total Mass DIN EN 127 Total Thickness | Automotive, |

| BMW TP 303.4 Climatic Test | Automotive, |

| BMW TS 384.2 Part 2.2 Heel Pad Test | Automotive, |

| BSDM 0500 Flammability for Interior Materials | Automotive, |

| BSDM 0503 Fogging Test Method for Interior Materials | Automotive, |

| BSDM 0505 Odor Evaluation | Automotive, |

| Chemical Resistance -Wiping Test | Automotive, |

| Chrysler 463LB-11-01B Pliability | Automotive, |

| Chrysler 463LB-11-01C Cold Cracking | Automotive, |

| Chrysler 463LB-12-01 Humidity/Hot/Cold Cycling | Automotive, |

| Chrysler 463LB-12-01 Humidity/Hot/Cold Cycling | Automotive, |

| Chrysler 463LB-13-01 Heat Aging | Automotive, |

| Chrysler Abrasion | Automotive, |

| Chrysler MS-JB-2000 (ASTM D5034) Breaking Strength | Automotive, |

| Chrysler Brush Test | Automotive, |

| Chrysler Flammability | Automotive, |

| Chrysler Friction test using 5 lb 5" disc 4"/min cross head seed and min 75 mm extension. Avg all directions repeat for 3 runs and average | Automotive, |

| Chrysler Heel Rub Test | Automotive, |

| Chrysler LP-463-11-01C Cold Cracking | Automotive, |

| Chrysler LP-463-10-01 Resistance to Humidity | Automotive, |

| Chrysler LP-463-31-01 Chemical Resistance | Automotive, |

| Chrysler LP-463CB-10-01/LP-463CB-03-01 Cold Age | Automotive, |

| Chrysler LP-463CB-10-01/LP-463CB-03-01 Heat,Humidity and Cold Aging | Automotive, |

| Chrysler LP-463DB-12-01 Fogging resistance | Automotive, |

| Chrysler LP-463DD-18-01 Determination of Scratch and Mar Resistance of Automotive Plastic | Automotive, |

| Chrysler LP-463KB-21-01 Resistance to Bearding & Fuzzing | Automotive, |

| Chrysler LP-463KB-34-01 Chrysler Antimicrobial Milk Test | Automotive, |

| Chrysler LP-463KB-37-02 Chrysler Stain Release Test | Automotive, |

| Chrysler LP-463KB-7-01 Seam Strength Test | Automotive, |

| Chrysler LP-463KC-01-01B Resistance to Dye Transfer | Automotive, |

| Chrysler LP-463KC-019 Resistance to Soiling | Automotive, |

| Chrysler LP-463KC-03-01B Water Spotting | Automotive, |

| Chrysler LP-463-KC-04-01 Cleanability Test | Automotive, |

| Chrysler LP-463-KC-04-01 General Cleanability of Trim Materials (Mopar) | Automotive, |

| Chrysler LP-463KC-04-01-2A Staining | Automotive, |

| Chrysler LP-463KC-04-01-2B Grease Cleanability | Automotive, |

| Chrysler LP-463-KC-04-01A Cleanable and Soil Resistance | Automotive, |

| Chrysler LP-463KC-04-02 Fluid Resistance & Cleanability | Automotive, |

| Chrysler LP-463KC-04-02 Soiling Test 4.3.2 Method 2 Hexapod | Automotive, |

| Chrysler LP-463KC-15-01 Resistance To Steaming | Automotive, |

| Chrysler LP-463LB 12-01 Peel Force After Aging | Automotive, |

| Chrysler LP-463LB-10-01 Bond Strength of Trim Materials | Automotive, |

| Chrysler LP-463LB-11-01 Pliability | Automotive, |

| Chrysler LP-463LB-11-01B Cold Flexibility | Automotive, |

| Chrysler LP-463LB-13-01 Heat Aging of Trim Materials | Automotive, |

| Chrysler LP-463PB Staining | Automotive, |

| Chrysler LP-463PB-31-01 Resistance of Paint Films to Various Fluids | Automotive, |

| Chrysler LP-463PB-31-01 Method J Solvent Wipe | Automotive, |

| Chrysler LP-463PB-31-01 Method J Xylene Wipe | Automotive, |

| Chrysler LP-463PB-53-01 Atmospheric Etch | Automotive, |

| Chrysler LP-463PB-54-01 Crock Mar Resistance | Automotive, |

| Chrysler LP-463TB-10-01 Shrinkage | Automotive, |

| Chrysler LP-46FB-37-03 Repellency Test | Automotive, |

| Chrysler MS-JB 2000 (ASTM D2261) Tearing Strength | Automotive, |

| Chrysler MS-JB 2000 (SAE J1351) Wet/Dry Odor | Automotive, |

| Chrysler MS-JB 2000 (SAE J883) Shrinkage | Automotive, |

| Chrysler MS-JB 2000 LP 463LB-10-01 Bond Strength Original, Heat Aged, After Cycling | Automotive, |

| Chrysler MS-JB 2000 LP-463KB-22-01 Tuft Lock | Automotive, |

| Chrysler MS-JB 2000 LP-463LB-11-01 Resistance to Cold Cracking | Automotive, |

| Chrysler MS-JB 2000 MS-JP-1-3 Salt Solution | Automotive, |

| Chrysler MS-JB-2000 (ASTM D5034) Breaking Strength | Automotive, |

| Chrysler MS-JB-2000 (SAE J1530) Resistance to Bearding and Fuzzing | Automotive, |

| Chrysler MS-JP-1-3 LP-463LB-12-01B Resistance to Humidity (Hot and Cold Cycles) 1 cycle | Automotive, |

| Chrysler MS-JP-1-3 LP-463LB-12-01B Resistance to Humidity (Hot and Cold Cycles) 2 and 3 cycles | Automotive, |

| Chrysler PF 8145 Section 4.8 Logo Retention Separation speed 51mm/mn | Automotive, |

| Chrysler PF 8145 Section 5.9 Fluid Retention/Transfer | Automotive, |

| Chrysler PF-11747 Clause 5.3 Pile Crush/Deformation | Automotive, |

| Chrysler PF-8145 Environmental | Automotive, |

| Chrysler PF-8145 Section 4.6 Grommets | Automotive, |

| Chrysler PF-8145 Section 5.4 Flatness/Warpage | Automotive, |

| Chrysler PF-8145 Section 6.2.14 | Automotive, |

| Chrysler Retention Coefficient of Friction | Automotive, |

| CMVSS 302 Automotive Flammability | Automotive, |

| Colorfastness to Light/Nissan Method M0135 1-11-2 (1 - 10 samples) | Automotive, |

| Consultation in Field ($2250/person/day+expenses) | Automotive, |

| Consultation In Laboratory ($300/person/hour) | Automotive, |

| CPSC Metals Analysis (Complete) | Automotive, |

| CPSC Wipe Test: Lead | Automotive, |

| Daimler DBL 5307 Burning Test | Automotive, |

| Daimler DBL 5399 Cleanability of Carpet | Automotive, |

| Daimler DBL 5452 Burning Behaviour | Automotive, |

| Daimler DBL 5452 Density | Automotive, |

| Daimler DBL 5452 Elongation at Break | Automotive, |

| Daimler DBL 5452 Part Weight | Automotive, |

| Daimler DBL 5452 Tensile Strength | Automotive, |

| Daimler DBL 5460.10 EPP | Automotive, |

| Daimler DBL 5872 8.10 Delamination DIN 53 357-A | Automotive, |

| Daimler DBL 5872 8.11 Dimensional Change DIN 53377 | Automotive, |

| Daimler DBL 5872 8.13 Climatic Resistance DBL 5471 5.3 Alternating Atmospheres | Automotive, |

| Daimler DBL 5872 8.14 Oxidative Aging | Automotive, |

| Daimler DBL 5872 8.18 Colorfastness to Rubbing ISO 105-X12 | Automotive, |

| Daimler DBL 5872 8.19 Soiling and Cleaning Behavior VDA 230-212 | Automotive, |

| Daimler DBL 5872 8.3 Weight (Layers) EN 12127 | Automotive, |

| Daimler DBL 5872 8.4 Thickness (Layers) ISO 9073-2 | Automotive, |

| Daimler DBL 5872 8.6 Linear Density of Yarn Filament Count | Automotive, |

| Daimler DBL 5872 8.8 Pile Fiber Setting Gauge Courses | Automotive, |

| Daimler DBL 5872 8.9 Tear Force ISO 13937-2 | Automotive, |

| Daimler DBL 5872: 8.3 Weight per unit area (EN 12127)/Layer Thickness EN ISO 9073-2 A and VDA 230-204 | Automotive, |

| Daimler DBL5307.10 Flammability | Automotive, |

| DIN 20 811 Water Resistance | Automotive, |

| DIN 53-109 Abrasion Resistance w/measurement and color change | Automotive, |

| DIN 53-121 Bending Stiffness | Automotive, |

| DIN 53356 Tearing Propagation Strength | Automotive, |

| DIN 53357 Laminate Adhesion Test | Automotive, |

| DIN 53357 Separation Force | Automotive, |

| DIN 53377 Dimensional Stability | Automotive, |

| DIN 53428 Water Absorption | Automotive, |

| DIN 53855-3 Total Thickness | Automotive, |

| DIN 54316 Imprinting Behavior/Visibility of Impression | Automotive, |

| DIN 54318 Dimensional Stability | Automotive, |

| DIN 54324 Rollstool | Automotive, |

| DIN 54325 Pile Layer Weight/Face Weight | Automotive, |

| DIN 54325 Pile Yarn Thickness | Automotive, |

| DIN 54345 TI Surface Resistance | Automotive, |

| DIN 75201A Fogging Characteristics | Automotive, |

| DIN 75-202 Determination of Colorfastness of Interior Materials in Motor Vehicles, Xenon Arc Lamp Test | Automotive, |

| DIN EN 12127 Total Weight Including Filament Tie Up | Automotive, |

| DIN EN 12127 Total Weight/Unit (Including all layers) | Automotive, |

| DIN EN 13036 Method for Measurement of Slip/Skid Resistance | Automotive, |

| DIN EN 13746 Dimensional Stability Due to Varied Conditions | Automotive, |

| DIN EN 14041 Resilient Floor Covering Characteristics | Automotive, |

| DIN EN 14808 Shock Absorption | Automotive, |

| DIN EN 150 105-B06 Colorfastness to Light | Automotive, |

| DIN EN 1903 Dimensional Changes after Accelerated Aging | Automotive, |

| DIN EN 20105-A02 Change in color before Aging According to Gray Scale | Automotive, |

| DIN EN 20105-A02/PR 121.1 Dirt Sensitivity/Visual Assessment | Automotive, |

| DIN EN 2813 Gloss | Automotive, |

| DIN EN 29073-1 Primary Backing Fleece | Automotive, |

| DIN EN 29073-1 Weight/Unit Area | Automotive, |

| DIN EN 29073-3 Tensile Strength & Elongation | Automotive, |

| DIN EN 388/PR 380 Puncture Resistance | Automotive, |

| DIN EN 388/PR 380 Puncture Resistance (Regular) | Automotive, |

| DIN EN 433 Dimensional Stability of Resilient Floor Tile after Exposure to Heat | Automotive, |

| DIN EN 433 Resilent Floor Coverings determination of Residual Indentation after Static Loading | Automotive, |

| DIN EN 53109 DIN EN 20105-A02 Taber Wear Characteristic | Automotive, |

| DIN EN 53455 Elongation | Automotive, |

| DIN EN 53855-3 Total Thickness Including All Layers | Automotive, |

| DIN EN 5470 Resistence to Wear | Automotive, |

| DIN EN ISO 13934 Tensile Properties of Fabrics VW50105 | Automotive, |

| DIN EN ISO 13934-1 Tear Strength (Room Temperature) | Automotive, |

| DIN EN ISO 15-X12 Abrasion | Automotive, |

| DIN EN ISO 24342 determination of side length, edge straightness, squareness of tiles | Automotive, |

| DIN EN12127 Total Weight per Unit | Automotive, |

| DIN EN29073 Weight per Unit Area | Automotive, |

| DIN EN 53855-3 Total Thickness Including All Layers | Automotive, |

| Edge Binding Strength Test | Automotive, |

| EDX and Scanning Electron Microscopy | Automotive, |

| Emblem Heat Resistance | Automotive, |

| Emblem Humidity Resistance | Automotive, |

| Emblem Thermo-Cycle (per cycle) | Automotive, |

| ES-X83239 Standard Test Method - Interior Plastic Parts Section 4.20 Wear Resistance | Automotive, |

| FIAT 9.03107 para 2.5.17 Method A/B Resistance to Efflorescence/Exudiation | Automotive, |

| Fisker Fluid Retention Test | Automotive, |

| Five Finger Scratch Test | Automotive, |

| Flex Test | Automotive, |

| Floor Trim Complete Test Battery | Automotive, |

| FMVSS 302 Automotive Flammability | Automotive, |

| FMVSS 302 Automotive Flammability After Aging | Automotive, |

| FMVSS Mattress | Automotive, |

| FMVSS302 Automotive Flammability (Single Burn) | Automotive, |

| Fogging Characteristics DIN 75201A | Automotive, |

| Ford FLTM 112 Cleanability and Soiling | Automotive, |

| Ford FLTM BL 108-02 Resistance to Abrasion | Automotive, |

| Ford FLTM BL 108-02 Resistance to Snagging | Automotive, |

| Ford FLTM BL 168-01 Fluid Resistance | Automotive, |

| Ford FLTM BL106-01 Weight | Automotive, |

| Ford FLTM BL109-01 Weight | Automotive, |

| Ford FLTM BN 057-01 Coefficient of Friction | Automotive, |

| Ford FLTM BN 103-01 Evaluation Procedure 2 | Automotive, |

| Ford FLTM BN 107-01 3.11.4 Soiling and Cleanability | Automotive, |

| Ford FLTM BN 113-01 Cycled Bond Strength | Automotive, |

| Ford FLTM BN 113-01 Original Bond Strength | Automotive, |

| Ford FLTM BN 113-01 Steamed Bond Strength | Automotive, |

| Ford FLTM BN 113-01 Wet Bond Strength | Automotive, |

| Ford FLTM BN108-02 Abrasion Resistance | Automotive, |

| Ford FLTM BO 040-01 Procedure A 80 degree C Short Term Environmental Cycling | Automotive, |

| Ford FLTM BO 040-01 Procedure B 80 degree C Long Term Environmental Cycling | Automotive, |

| Ford FLTM BO 131-01/SAE J1351 Odor Assessment | Automotive, |

| Ford FLTM BO 131-03 Odor | Automotive, |

| FORD FLTM BP 101, Procedure A Ozone Resistance | Automotive, |

| Ford WSS-M15P44-B 3. Photometric Fogging | Automotive, |

| Ford WSS-M15P44-B 3.10 Water Shrinkage | Automotive, |

| Ford WSS-M15P44-B 3.10.10 Cold Resistance | Automotive, |

| Ford WSS-M15P44-B 3.10.12 Cold Temperature Curl | Automotive, |

| Ford WSS-M15P44-B 3.10.13 Coefficient of Friction | Automotive, |

| Ford WSS-M15P44-B 3.10.3 Dimensional Stability | Automotive, |

| Ford WSS-M15P44-B 3.10.4 Tensile Strength | Automotive, |

| Ford WSS-M15P44-B 3.10.5 Tensile After Aging | Automotive, |

| Ford WSS-M15P44-B 3.10.6 Trapezoidal Tear | Automotive, |

| Ford WSS-M15P44-B 3.10.7 Pile Tuft Pull Strength (6 ways) | Automotive, |

| Ford WSS-M15P44-B 3.10.8 Resistance to Heat | Automotive, |

| Ford WSS-M15P44-B 3.10.9 Adhesion to Substrate | Automotive, |

| Ford WSS-M15P44-B 3.11 Migration Staining | Automotive, |

| Ford WSS-M15P44-B 3.11 Taber Abrasion | Automotive, |

| Ford WSS-M15P44-B 3.12.1 Resistance to Interior Weathering | Automotive, |

| Ford WSS-M15P44-B 3.12.2 Fiber Deterioration after UV | Automotive, |

| Ford WSS-M15P44-B 3.12.3 Crocking | Automotive, |

| Ford WSS-M15P44-B 3.12.4 Long Term Environmental | Automotive, |

| Ford WSS-M15P44-B 3.12.5 Soiling and Cleanability | Automotive, |

| Ford WSS-M15P44-B 3.13 Flammability | Automotive, |

| Ford WSS-M15P44-B 3.2 Heat Shrinkage | Automotive, |

| Ford WSS-M15P44-B 3.5 Appearance | Automotive, |

| Ford WSS-M15P44-B 3.7 Mildew | Automotive, |

| Ford WSS-M15P44-B 3.8 Odor | Automotive, |

| Ford WSS-M15P44-B 3.9 Fogging | Automotive, |

| Ford WSS-M15P44-B Clip Test Portion (several replicates) | Automotive, |

| Ford WSS-M8P16-B Adhesion | Automotive, |

| Ford WSS-M8P16-B Breaking Load | Automotive, |

| Ford WSS-M8P16-B Fiber deterioration (after Fade exposure) | Automotive, |

| Ford WSS-M8P16-B Flammability ISO 3795 | Automotive, |

| Ford WSS-M8P16-B FLTM BN 106-01 Weight | Automotive, |

| Ford WSS-M8P16-B FLTM BN 107-01 Resistance to Crocking | Automotive, |

| Ford WSS-M8P16-B FLTM BN 112-08 Soiling and Cleanability | Automotive, |

| Ford WSS-M8P16-B FLTM BO 040-01 Long term Cycling | Automotive, |

| Ford WSS-M8P16-B FLTM BO 040-01 Short term Cycling | Automotive, |

| Ford WSS-M8P16-B FLTM BO131-03 Odor | Automotive, |

| Ford WSS-M8P16-B Fogging | Automotive, |

| Ford WSS-M8P16-B Heat Aging | Automotive, |

| Ford WSS-M8P16-B Mildew Resistance | Automotive, |

| Ford WSS-M8P16-B Resistance to Abrasion (6 sample test) | Automotive, |

| Ford WSS-M8P16-B Resistance to Fade 225.6 kj | Automotive, |

| Ford WSS-M8P16-B Resistance to Snagging (6 sample test) | Automotive, |

| Ford WSS-M8P16-B Tear Strength | Automotive, |

| Ford WSS-M99P48-A3 Section 3.2.8 Interior Application | Automotive, |

| Freeze Then Cyclic Testing | Automotive, |

| GCMS Gas Chromatographic Mass Spectrometer | Automotive, |

| GM GM 2715M Abrasion Resistance (< 5,000 cycles w/ weight loss) | Automotive, |

| GM GM 3026 Abrasion | Automotive, |

| GM GM 3026 Color Crocking | Automotive, |

| GM GM 3026 Dimensional Stability GMW 4217 | Automotive, |

| GM GM 3026 Mold Mildew 3259 | Automotive, |

| GM GM 3026 Water Spotting 14103 | Automotive, |

| GM GM 3208 Abrasion Resistance (3 samples) | Automotive, |

| GM GM 3402 Cleanability and Soil Resistance | Automotive, |

| GM GM 7457 Automotive Battery | Automotive, |

| GM GM 9070P Flammability (As Received) | Automotive, |

| GM GM 9070P Flammability with Aging | Automotive, |

| GM GM 9126P Cleanability | Automotive, |

| GM GM 9133P Resistance to Water Spotting and Salt Staining | Automotive, |

| GM GM 9771P Fiber Degradation | Automotive, |

| GM GMW 14102 Water Spotting | Automotive, |

| GM GMW 14108 Bending at Cold Temperature | Automotive, |

| GM GMW 14124 Cycle M Environmental Shrinkage | Automotive, |

| GM GMW 14125 Linear Abrasion | Automotive, |

| GM GMW 14125 Stability of Materials | Automotive, |

| GM GMW 14141 Dye Migration | Automotive, |

| GM GMW 14148 Tuft Bind | Automotive, |

| GM GMW 14162 Cycle A Colorfastness to Light | Automotive, |

| GM GMW 14162 Cycle B Colorfastness to Light | Automotive, |

| GM GMW 14196 3.10 Compression Set | Automotive, |

| GM GMW 14334 Chemical Resistance to Fluids | Automotive, |

| GM GMW 14444 Adhesion | Automotive, |

| GM GMW 14444 Chemical Resistance Section 3.4.16 | Automotive, |

| GM GMW 14444 Cleanability and Soil Resistance | Automotive, |

| GM GMW 14444 Compatibility | Automotive, |

| GM GMW 14444 Humidity Aging | Automotive, |

| GM GMW 14444 Protective Tape Foil Compatibility | Automotive, |

| GM GMW 14444 Resistance to Cleaning Agents | Automotive, |

| GM GMW 14444 Resistance to Cleaning Agents section 3.4.19 | Automotive, |

| GM GMW 14444 Section 4.5.11 Dimensional Stability Cycle M | Automotive, |

| GM GMW 14573 6d Heat Aging | Automotive, |

| GM GMW 14573 Resistance to Fluids | Automotive, |

| GM GMW 14892 Adhesion | Automotive, |

| GM GMW 15635 Carbonyl VOC/SVOC for Floor Mat | Automotive, |

| GM GMW 15812 UV Testing 1737 hours exposure | Automotive, |

| GM GMW 16015 Floor Mat Retention Test | Automotive, |

| GM GMW 16061 Retention Performance of Exterior Emblems and Nameplates | Automotive, |

| GM GMW 16443 Type II Applications Test Data | Automotive, |

| GM GMW 16692 4.3.1 Floor Mat Retainers | Automotive, |

| GM GMW 16692 4.3.2 Floor Mat Retainers-Step on Loading | Automotive, |

| GM GMW 16692 4.3.3 Floor Mat Retainers-Mat Tear after a Peel Pull | Automotive, |

| GM GMW 16853 | Automotive, |

| GM GMW 17595 Floor Mat Frictional Force | Automotive, |

| GM GMW 2026 3259 Mold Mildew | Automotive, |

| GM GMW 3010 Tensile Strength | Automotive, |

| GM GMW 3026 Dimensional Stability GMW 4217 | Automotive, |

| GM GMW 3026 14103 Water Spotting | Automotive, |

| GM GMW 3026 14108 Resistance to Cold Cracking | Automotive, |

| GM GMW 3026 3.2.1 Weight 3d | Automotive, |

| GM GMW 3026 3.2.10 Odor 8d | Automotive, |

| GM GMW 3026 3.2.11 Mildew 15d | Automotive, |

| GM GMW 3026 3.2.12 Fogging 10d | Automotive, |

| GM GMW 3026 3.2.13 Flammability-As Received and after Aging 13d | Automotive, |

| GM GMW 3026 3.2.14 Dimensional Stability 8d | Automotive, |

| GM GMW 3026 3.2.2 Pile Height 3d | Automotive, |

| GM GMW 3026 3.2.3 Thickness 3d | Automotive, |

| GM GMW 3026 3.2.4 Breaking Load 5d | Automotive, |

| GM GMW 3026 3.2.5 Trouser Tear Strength | Automotive, |

| GM GMW 3026 3.2.6 Resistance to Cracking from Bending at Cold Temp | Automotive, |

| GM GMW 3026 3.2.7 Loop Pile Pullout 5d | Automotive, |

| GM GMW 3026 3.2.8 Abrasion Resistance 5d | Automotive, |

| GM GMW 3026 3.2.9 Stability of Materials against Mechanical Load 5d | Automotive, |

| GM GMW 3026 3.3.1 Colorfastness to Artificial Light 24d (up to 5 colors) | Automotive, |

| GM GMW 3026 3.3.3 Fiber Degradation 15d | Automotive, |

| GM GMW 3026 3.3.4 Dye Migration 8d | Automotive, |

| GM GMW 3026 3.3.5 Color Crock 5d | Automotive, |

| GM GMW 3026 3.3.6 Water Spotting/Colorfastness to Water 8d | Automotive, |

| GM GMW 3026 3.3.7 Cleanability and Soil Resistance 10d | Automotive, |

| GM GMW 3026 3010 Tensile Strength | Automotive, |

| GM GMW 3026 3259 Odor | Automotive, |

| GM GMW 3026 Abrasion Resistance (3 samples) | Automotive, |

| GM GMW 3026 APPENDIX A (A.1 Data Sheet) | Automotive, |

| GM GMW 3026 APPENDIX A (A.2 Data Sheet) | Automotive, |

| GM GMW 3026 APPENDIX A (A.3 Formed Carpet Construction Certification Data Sheet) | Automotive, |

| GM GMW 3026 APPENDIX A (FULL BATTERY) | Automotive, |

| GM GMW 3026 APPENDIX B3 Formed Carpet Construction Certification Data Form | Automotive, |

| GM GMW 3026 Color Crocking | Automotive, |

| GM GMW 3026 Colorfastness to Light 3.3 | Automotive, |

| GM GMW 3026 Pile Thickness | Automotive, |

| GM GMW 3026 Trouser Tear Strength | Automotive, |

| GM GMW 3182 Pile Height | Automotive, |

| GM GMW 3182 Pile Weight | Automotive, |

| GM GMW 3205 Odor Evaluation | Automotive, |

| GM GMW 3208 Abrasion Resistance Type III 2400 cycles | Automotive, |

| GM GMW 3232 Automotive Flammability (Individual Burns) | Automotive, |

| GM GMW 3232 Automotive Flammability (Individual Burns) | Automotive, |

| GM GMW 3232 Flammability with Aging | Automotive, |

| GM GMW 3235 Method B, T2 Fogging | Automotive, |

| GM GMW 3387 Fiber Degradation | Automotive, |

| GM GMW 3402 Cleanability and Soil Resistance | Automotive, |

| GM GMW 4217 Shrinkage | Automotive, |

| GM GMW 5757 APPENDIX A | Automotive, |

| GM GMW 8081 Static Head space GCMS for Interior Materials | Automotive, |

| GM GMW 9771P Fiber Degradation | Automotive, |

| GM GMW Physical Certification Battery | Automotive, |

| GM236SOP Mold/Mildew | Automotive, |

| GME 60-276 Odor Analysis | Automotive, |

| Grommet Removal Force | Automotive, |

| Grommet Strength | Automotive, |

| GS 93026-1 5.10 BMW Compression Set Resistance Section 3.1 | Automotive, |

| GS 97034-5 Resistance to Cleaning Agents | Automotive, |

| GS 97034-6 Soiling Behavior and Cleaning Ability: Procedure B | Automotive, |

| GS 97034-9 Scratch Test | Automotive, |

| GS 97038 Flammability | Automotive, |

| Heat Aged (ISO 188/ASTM D573, 150? 50 air changes/h. 168 h at 70? 2 C) | Automotive, |

| Heat Aging and Cycled Environment Exposure (Cycled and Heat Age) | Automotive, |

| Heat Aging Environment Exposure (Heat Only) | Automotive, |

| Heat Aging per day | Automotive, |

| Heat Resistance | Automotive, |

| Heat Resistance (7M8606) | Automotive, |

| Heel Impact | Automotive, |

| High Temp/Low Temp Bend Test | Automotive, |

| Honda 1.3 Peel Strength | Automotive, |

| Honda Abrasion Test with a Heel Rub | Automotive, |

| Honda Breaking Strength | Automotive, |

| Honda HES 6.23 Heel Wear Resistance | Automotive, |

| Honda HES 6506 5.11.2 Crocking | Automotive, |

| Honda HES 8330Z-T20A-000 6-21 Penetration Strength | Automotive, |

| Honda HES 8360X-TR0-A000 7-15 Emblem Peeling Strength | Automotive, |

| Honda HES 8360X-TR0-A000 7-3 Emblem Heat Resistance 80?C for 100 hours | Automotive, |

| Honda HES 8360X-TR0-A000 7-4 Emblem Humidity Resistance 50?C for 100 hours..95% Relative Humidity.. | Automotive, |

| Honda HES 8360X-TR0-A000 7-5 Hygrothermal Cycle Resistance to 10 Cycles of: 80?C for 2 hours..23?C for 2 hours..-30?C for 2 hours..23?C for 2 hours.. | Automotive, |

| Honda HES 8360X-TR0-A000 7-7 Shoes Friction Durability (Emblem Included) | Automotive, |

| Honda HES 8360Z Grommet 80 degrees C | Automotive, |

| Honda HES 8360Z Grommet Normal Temperature | Automotive, |

| Honda HES 8360Z Grommet Pull Out Force | Automotive, |

| Honda HES 8360Z Nib Strength | Automotive, |

| Honda HES 8360Z Overmolding Tears and Separation | Automotive, |

| Honda HES 8360Z TGSB-A000 Section 7-24 Nib Strength | Automotive, |

| Honda HES 8360Z-T20-A0000 (7-7) Shoe Wear Resistance | Automotive, |

| Honda HES 8360Z-TGS-A000 7.1 Light Resistance | Automotive, |

| Honda HES 8360Z-TR0-A000 (6-19) Odor Properties HES D 6507 4.16 | Automotive, |

| Honda HES 8360Z-TR0-A000 (6-20) Heat Resistance HES D 6507 4.18 | Automotive, |

| Honda HES 8360Z-TR0-A000 (6-6) Sliding Load | Automotive, |

| Honda HES 8360Z-TR0-A000 (6-9) Over Sewing Abrasion Test with Resin of Shore A Hardness 95 | Automotive, |

| Honda HES 8360Z-TR0-A000 (7-11) Pile Pull Out Strength | Automotive, |

| Honda HES 8360Z-TR0-A000(6-10) Wet Heat Aging Properties HESD 6507 4.174 | Automotive, |

| Honda HES 8360Z-TR0-A000(6-11) Taber Abrasion Strength ASTM D1175 (H-18, 4,000, 70r/min, 500gf) | Automotive, |

| Honda HES 8360Z-TR0-A000(6-12) Strength of Emblem | Automotive, |

| Honda HES 8360Z-TR0-A000(6-16) Strength of Ring | Automotive, |

| Honda HES 8360Z-TR0-A000(6-17) Color Fastness to Washing HES D 6506 5.11.1 | Automotive, |

| Honda HES 8360Z-TR0-A000(6-21) Haze (Fogging) HESD 6508 | Automotive, |

| Honda HES 8360Z-TR0-A000(6-22-1) Sound absorption Air permeability | Automotive, |

| Honda HES 8360Z-TR0-A000(6-4) Water Penetration | Automotive, |

| Honda HES 8360Z-TR0-A000(6-5) Shoe Wear Resistance | Automotive, |

| Honda HES C210 Pile Pull Out Strength (Water Soaked) | Automotive, |

| Honda HES C210-00 4.16 Odor Property | Automotive, |

| Honda HES D6003 Flammability (Preconditioning Aging) | Automotive, |

| Honda HES D6003 Flammability w/Aging | Automotive, |

| Honda HES D6057-00 4.18 Heat Resistance | Automotive, |

| Honda HES D6506 5.11.2 Colorfastness to Rubbing | Automotive, |

| Honda HES D6506 5.12 Dimensional Change in Water | Automotive, |

| Honda HES D6506 5.26 Dimensional Change in Heat | Automotive, |

| Honda HES D6506 5.8 Flexibility | Automotive, |

| Honda HES D6506 Section 29 Electrification | Automotive, |

| Honda HES D6506 Tuft Bind | Automotive, |

| Honda HES D6506-00 5.11.1 Colorfastness to Washing | Automotive, |

| Honda HES D6507 4.11 Crease Resistance | Automotive, |

| Honda HES D6507 4.12 Abrasion Strength | Automotive, |

| Honda HES D6507 4.13.1 Light Resistance UV Carbon | Automotive, |

| Honda HES D6507 4.17 Wet Heat Aging | Automotive, |

| Honda HES D6507 4.18 Heat Resistance | Automotive, |

| Honda HES D6507 4.2 Thickness | Automotive, |

| Honda HES D6507 4.3 Compressibility | Automotive, |

| Honda HES D6507 4.3 Compressive Modulus | Automotive, |

| Honda HES D6507 4.4.1 Tensile Strength Original State | Automotive, |

| Honda HES D6507 4.4.2 Tensile Strength Wet | Automotive, |

| Honda HES D6507 4.6 Peel Strength | Automotive, |

| Honda HES D6507 4.7.1 Pile Pull Out Strength | Automotive, |

| Honda HES D6507 4.7.2 Pile Pull Out Strength | Automotive, |

| Honda HES D6507 4.8 Pile Fall Off Strength | Automotive, |

| Honda HES D6507 5.11.1 Colorfastness to Washing | Automotive, |

| Honda HES D6507 6.9 Over Sewing Abrasion Test | Automotive, |

| Honda HES D6507 Colorfastness to Rubbing | Automotive, |

| Honda HES D6507 Odor Analysis | Automotive, |

| Honda HES D6508 Honda Haze Fogging Test | Automotive, |

| Honda HES D6511 4.6 Tear Strength Method A (Single Tongue) | Automotive, |

| Honda HES D6601 Colorfastness to Light (Additional Samples) | Automotive, |

| Honda HES D6601,3 Light Resistance (Xenon) | Automotive, |

| Honda HES Peel Strength | Automotive, |

| Honda HES Sliding Load | Automotive, |

| Honda HES Sound Absorption/Air Permeability | Automotive, |

| Honda HES Standard Testing | Automotive, |

| Honda HES Tensile Strength | Automotive, |

| Honda HES Volatiles Test Method 0094ZT0A | Automotive, |

| Honda HES Water Penetration | Automotive, |

| Honda HES Water Resistance | Automotive, |

| Honda Piercing Test (puncture) | Automotive, |

| Honda Procedure Delamination | Automotive, |

| Honda Section 16 Testing Strength of Ring | Automotive, |

| Honda Sliding Load | Automotive, |

| Honda SW6 Pile Draw Out Strength | Automotive, |

| Honda TROA000 Section 16 Testing Strength of Ring Ambient & Temp (5 replicates) | Automotive, |

| Honda TROA000 Testing Strength of Ring Section 16 - Degrees | Automotive, |

| Honda TROA000 Testing Strength of Ring Section 16 - Normal | Automotive, |

| Honda VOC | Automotive, |

| Honda Water Penetration | Automotive, |

| Honda Water Permeability | Automotive, |

| Humidity Resistance Method B | Automotive, |

| Hyundai Colorfastness to Light (1-10 Samples) | Automotive, |

| Hyundai MOBIS EF1400-T-01 Section 5.1.5 5.3 Grommet Separation Force | Automotive, |

| Hyundai MOBIS EF1400-T-01 Section 5.2.1 Fixed Pull Test | Automotive, |

| Hyundai MOBIS EF1400-T-01 Section 5.2.2 Shear Friction | Automotive, |

| Hyundai MOBIS EF1400-T-01 Section 5.5 Mat Abrasion | Automotive, |

| Hyundai MOBIS MS210 Section 4.10 Impact Resistance Room Temperature and Low Temperature | Automotive, |

| Hyundai MOBIS MS210 Section 4.3.1 Heat Cycle Resistance | Automotive, |

| Hyundai MOBIS MS210 Section 4.3.2 Thermal Shock Resistance | Automotive, |

| Hyundai MOBIS MS210 Section 4.4 Heat Aging Resistance | Automotive, |

| Hyundai MOBIS MS300 Section 4.15 Low Temperature Resistance | Automotive, |

| Interior Parts visible inspection criteria | Automotive, |

| ISO 105 Colourfastness to Water | Automotive, |

| ISO 105-A01 Color Crock | Automotive, |

| ISO 105-A02 Grey scale for assessing change in colour | Automotive, |

| ISO 105-B02 Lightfastness (1 Cycle) | Automotive, |

| ISO 105-B02 Lightfastness (3 Cycles) | Automotive, |

| ISO 105-B02 method 3-colorfastness to light | Automotive, |

| ISO 105-B02:1994 Colorfastness to Artificial Light | Automotive, |

| ISO 105-B06 Condition 5 Colorfastness to light | Automotive, |

| ISO 105-E01 textile-test for colour fastness part E-01 | Automotive, |

| ISO 105-X12 Rubbing (Dry) | Automotive, |

| ISO 105-X12 Rubbing (Wet) | Automotive, |

| ISO 811 Determination of Resistance to Water Penetration-Hydrostatic Pressure Test | Automotive, |

| Jaguar:AN101-01Bleed | Automotive, |

| Jaguar:FLTMBN-105-01 | Automotive, |

| Jaguar:FLTMBN-105-03 | Automotive, |

| Jaguar:FLTMBN-105Wt | Automotive, |

| Jaguar:FLTMBN-106-01 | Automotive, |

| Jaguar:FLTMBN107-01 | Automotive, |

| Jaguar:FLTMBN-112-08 | Automotive, |

| Jaguar:ISO 105-A02 | Automotive, |

| Jaguar:JNS30.21.07Dr | Automotive, |

| Jaguar:JNS30.21.07Wt | Automotive, |

| JCP-PP06-0902 Coefficient of Friction of Skid Resistant Materials | Automotive, |

| KIA VG SPECIFICATION SUMMARY (includes)..MS 343-17..MS 300-35..MS 210-05 Xenon and Heat Cycle..MS 210-05 Odor..SAE J1756..MS 201-02 | Automotive, |

| Lexus 7.1 Mass | Automotive, |

| Lexus 7.10 Flammability (as received and after aging) | Automotive, |

| Lexus 7.12 Odor Analysis (wet and dry) | Automotive, |

| Lexus 7.13 Crocking Method A & B | Automotive, |

| Lexus 7.16 Colorfastness to Light and Light Aging | Automotive, |

| Lexus 7.2 Thickness | Automotive, |

| Lexus 7.3 Tensile Strength (Warp & Weft) | Automotive, |

| Lexus 7.4 Tear Strength (Warp Weft) | Automotive, |

| Lexus 7.5.1 & 7.5.2 Abrasion Stringiness and Tear and Loss | Automotive, |

| Lexus 7.6 Heat Shrinkage | Automotive, |

| Lexus 7.7 Rigidity | Automotive, |

| Lexus 7.8 Tensile Strength After Heating (Warp & Weft) | Automotive, |

| Lexus 7.9 Change in Length between gages (warp & weft) | Automotive, |

| Liquid Resistance | Automotive, |

| Low Temp Flex | Automotive, |

| Low Temperature Resistance | Automotive, |

| Materials Analysis: Microscopy | Automotive, |

| Mazda Lightfastness 14.1 mj | Automotive, |

| Mazda Mat Movement on Bench | Automotive, |

| Mazda MES MN 405 7.12 Pile Draw Out Strength | Automotive, |

| Mazda MES MN 405 7.14.3 Method C Mazda Standard (Abrasion) | Automotive, |

| Mazda MES MN 405 7.15 Pilling & Fuzzing | Automotive, |

| Mazda MES MN 405 7.21 Colorfastness to Rubbing | Automotive, |

| Mazda MES MN 405 7.22 Colorfastness to Wash | Automotive, |

| Mazda MES MN 405 7.23.1 Method A-B Colorfastness to Light (1 - 10 samples at 14.1 mj) | Automotive, |

| Mazda MES MN 405 7.23.1 Method A-B Colorfastness to Light (1 - 10 samples) | Automotive, |

| Mazda MES MN 405 7.24.1 Method A Light Aging Resistance | Automotive, |

| Mazda MES MN 405 7.24.3 Method AC Light Aging Resistance | Automotive, |

| Mazda MES MN 405 7.25 Colorfastness to Heat | Automotive, |

| Mazda MES MN 405 7.29 Heat Aging of Backing Material | Automotive, |

| Mazda MES MN 405 7.30 Loss of Heating | Automotive, |

| Mazda MES MN 405 7.31 Stickiness | Automotive, |

| Mazda MES MN 405 7.32.1 Cold Resistance | Automotive, |

| Mazda MES MN 405 7.38 Mildew | Automotive, |

| Mazda MES MN 405 7.5.1 Tensile & Elongation (Strip Method) | Automotive, |

| Mazda MES MN 405 7.6.1 Tear Strength Method A | Automotive, |

| Mazda MES MN 405 7.7 Chemical Fluid Resistance (Symbol Cr) | Automotive, |

| Mazda MES MN 405 Abrasion Resistance Method B-a | Automotive, |

| Mazda MES MN 405 Section 7.7 Constant Load Elongation | Automotive, |

| Mazda MES PW PT0001 Section 7.3 Short Term Heat Resistance | Automotive, |

| Mazda MES PW PT0001 Section 7.4 Long Term Heat Resistance | Automotive, |

| Mazda MES PW PT001 Section 7.5 Cold Resistance | Automotive, |

| Mazda MES PW PT001 Section 7.6 Thermal Cycle | Automotive, |

| Mazda MES PW PT001 Section 7.8 Weatherability $9 per hour | Automotive, |

| MBN 55555-6/DBL 5471 | Automotive, |

| Mechanical Cycling | Automotive, |

| Mercedes PWT 7301 Heel Abrasion Test | Automotive, |

| Mercury Scans | Automotive, |

| Microphotographs | Automotive, |

| MIL-DTL-44048H ASTM D5034 Button Pull | Automotive, |

| Mitsubishi EX 60410 Flammability | Automotive, |

| MS 200-48 Chemical Resistance | Automotive, |

| MS 200-48 Water Resistance | Automotive, |

| MS 210-05 4.3 Heat Cycle Resistance | Automotive, |

| MS 210-05 Fading Resistance Test | Automotive, |

| MS 210-05 Scratch Resistance | Automotive, |

| MS 300-08 Flammability 10 burns (aged) | Automotive, |

| MS 300-08 Flammability 10 burns (as received) | Automotive, |

| MS 300-08 Flammability Aging | Automotive, |

| MS 300-34 Odor Evaluation | Automotive, |

| MS 300-35 Section 4.7 Tuft Lock | Automotive, |

| MS 300-35 Section 4.9 Tabor Resistance | Automotive, |

| MS 711-12 A1 Hyundai/Kia | Automotive, |

| MS JP 9-5 UV Exposure (1600 hours) | Automotive, |

| MS.90075 Pressure Sensitive Adhesives on Components for Sound Suppression, Vibration Damping and Heat Insulation Purposes | Automotive, |

| MS-HB 2000 MS-JP-1-3 Salt Solution 10 cycles | Automotive, |

| MS-JP-9-4 |

Automotive, |

| Nissan NES 7105.11 Cold Resistance | Automotive, |

| Nissan NES 74902NDS00, 5-4 D Adhesion Test | Automotive, |

| Nissan NES G4900NADAS0 Section 18 Friction Test | Automotive, |

| Nissan NES M0076 Acceptance | Automotive, |

| Nissan NES M0076 Appearance Colorimetric Evaluation | Automotive, |

| Nissan NES M0076 Colorfastness to Rubbing | Automotive, |

| Nissan NES M0076 Colorfastness to Water | Automotive, |

| Nissan NES M0076 Electrostatic Characteristics Section 18 | Automotive, |

| Nissan NES M0076 Peeling Force | Automotive, |

| Nissan NES M0076 Section 20 Mildew Resistance | Automotive, |

| Nissan NES M0076 Section 33 Fogging | Automotive, |

| Nissan NES M0076 Tear Strength | Automotive, |

| Nissan NES M0076 Tensile Strength | Automotive, |

| Nissan NES M0076 Yellowing by Nitrogen Oxides Section 17B | Automotive, |

| Nissan NES M0076.12 Breaking Strength and Elongation | Automotive, |

| Nissan NES M0076.14 Tuft Bind | Automotive, |

| Nissan NES M0076.16 Abrasion Resistance | Automotive, |

| Nissan NES M0076.21 Resistance to Light (1-10 Samples) | Automotive, |

| Nissan NES M0076.21 Resistance To Light Additional Sample | Automotive, |

| Nissan NES M0076.24 Shrinkage Test | Automotive, |

| Nissan NES M0076.25 Thermal Cycle Test | Automotive, |

| Nissan NES M0076.27 High Temperature Heat Resistance | Automotive, |

| Nissan NES M0076.32 Water Repellance | Automotive, |

| Nissan NES M0076.34 Odor Test | Automotive, |

| Nissan NES M0094 Flammability of Interior Materials for Automobiles | Automotive, |

| Nissan NES M0131 High Temperature Test | Automotive, |

| Nissan NES M0131 Methods of High Temperature Test for Passenger Compartment Synthetic Resin Parts | Automotive, |

| Nissan NES M0132 Methods of Thermal Cycle Testing for Plastic Parts | Automotive, |

| Nissan NES M0133 Method 2 Chemical Resistance | Automotive, |

| Nissan NES M0133 Method 2 Chemical Resistance for Plastic Parts ($12/chemical) | Automotive, |

| Nissan NES M0135 Resistance to Light at 25 mJ (Additional Samples) | Automotive, |

| Nissan NES M0135 Weatherability and Light Resistance (1-10 Samples) | Automotive, |

| Nissan NES M0136 Abrasion Resistance for Plastic Parts | Automotive, |

| Nissan NES M0138 Metal Grommet | Automotive, |

| Nissan NES M0140 Salt Spray Exposure | Automotive, |

| Nissan NES M0141 Section 6.2.9 Scratch Resistance (Method 5) | Automotive, |

| Nissan NES M0153 Method 4 Type 2 Humidity Cycle | Automotive, |

| Nissan NES M0153 Moisture Resistance for Plastic Parts | Automotive, |

| Nissan NES M0154 Dry Cloth Friction Colorfastness Test (Reference JIS L 0849) | Automotive, |

| Nissan NES M0154 Test # 17 Seam Fatigue | Automotive, |

| Nissan NES M0154 Test #23 Scratch Resistance Test | Automotive, |

| Nissan NES M0154 Test #27 Fray Resistance Test | Automotive, |

| Nissan NES M0158 Compound Corrosion Test | Automotive, |

| Nissan NES M0159 Scratch Resistance of Plastic Resins (D1 and D2) | Automotive, |

| Nissan NES M0160 Odor Evaluation | Automotive, |

| Nissan NES M0161 Fogging Characteristics | Automotive, |

| Nissan NES M0402 VOC | Automotive, |

| Nissan NES M5081 Conductive Paint Surface Electrical Resistance | Automotive, |

| Nissan NES M7103 Odor Evaluation | Automotive, |

| Nissan NES M7105 Chemical Resistance | Automotive, |

| Nissan NES M7105 Clouding Value (Fogging) | Automotive, |

| Nissan NES M7105 Section 13 Dry Cloth Friction Resistance | Automotive, |

| Nissan NES M7105.14 Thermal Resistance | Automotive, |

| Nissan NES M7105.9 Adhesiveness | Automotive, |

| Nissan NES M8506 Test Method 5.11 Adhesive 23 degrees C | Automotive, |

| Nissan NES M8506 Test Method 5.11 Adhesive 5 degrees C | Automotive, |

| Nissan NES M8506 Test Method 5.12 Room Temp Adhesion 23 degrees C Peel Strength | Automotive, |

| Nissan NES M8506 Test Method 5.12 Room Temp Adhesion 23 degrees C Shear Holding Force | Automotive, |

| Nissan NES M8506 Test Method 5.12 Room Temp Adhesion 23 degrees C Shear Strength | Automotive, |

| Nissan NES M8506 Test Method 5.13 High Temp Adhesive Performance Class 1 90 degrees C Peel Strength | Automotive, |

| Nissan NES M8506 Test Method 5.13 High Temp Adhesive Performance Class 1 90 degrees C Shear Strength | Automotive, |

| Nissan NES M8506 Test Method 5.13 High Temp Adhesive Performance Class 1 90 degrees C Shear Holding Force | Automotive, |

| Nissan NES M8506 Test Method 5.17 Heat Aging Peel Strength | Automotive, |

| Nissan NES M8506 Test Method 5.17 Heat Aging Shear Strength | Automotive, |

| Nissan NES M8506 Test Method 5.18 Humidity Resistance Peel Strength | Automotive, |

| Nissan NES M8506 Test Method 5.7 Appearance | Automotive, |

| Nissan NES M8506 Test Method 5.8 Storage Stability Peel Strength | Automotive, |

| Nissan NES M8506 Test Method 5.8 Storage Stability Shear Strength | Automotive, |

| Nissan NES Mass | Automotive, |

| Nissan Single Cable/Bungee Loop/Elastic Band Strength | Automotive, |

| O2 Aging Test | Automotive, |

| Oil Resistance | Automotive, |

| Oven Aging Resistance | Automotive, |

| PF 8145 Environmental | Automotive, |

| PF 8145 Section 4.8 Logo Retention Separation speed 51mm/mn | Automotive, |

| Photographs | Automotive, |

| PR 2.2.4.3 Separation Force Reference DIN 54 310 | Automotive, |

| PR 2.3.1 Shear Force | Automotive, |

| PR 2.3.5 Holding Force | Automotive, |

| PR 2.3.6 Service Life Test of the Fastneing System (Shear Load, Dismantling) | Automotive, |

| PR 2.4.1. Climate Change according to PR 303.4 a | Automotive, |

| PR 2.4.6 Shearing Load | Automotive, |

| PR 305.5a Climatic Change | Automotive, |

| PR 380 2.2.5 Adhesion Force | Automotive, |

| PR 380 2.3.4 Adhesion Strength | Automotive, |

| PR 380:2009-09 2.4.1 - 2.4.5 | Automotive, |

| PR 381.4 Floor Trim Specification Battery | Automotive, |

| PT 7301 Heel Rub Analysis (Full) | Automotive, |

| Resistance to Staining - Salt | Automotive, |

| Rivian RTS.1661 Interior Material - Soiling | Automotive, |

| Rivian RTS.1744 Interior Material - Accelerated Weathering | Automotive, |

| Rivian RTS.1746 Interior Material - Abrasion Resistance | Automotive, |

| Rivian RTS.1749 Interior Material - Cleaner Resistance | Automotive, |

| Rivian RTS.1750 Interior Material - Chemical Resistance | Automotive, |

| Rivian RTS.1754 Interior Material - Odor | Automotive, |

| Rivian RTS.1755 Interior Material - Fogging | Automotive, |

| Rivian RTS.1758 Interior Material - Breaking Strength | Automotive, |

| Rivian RTS.1759 Interior Material - Fabric Elongation | Automotive, |

| Rivian RTS.1761 Interior Material - Cold Flexibility | Automotive, |

| Rivian RTS.1771 Interior Material - Trapezoid Tear | Automotive, |

| Rivian RTS.1938 Interior Material - Coefficient of Friction | Automotive, |

| Rivian RTS.2004 Interior Material - Shrinkage | Automotive, |

| Rivian RTS.3191 Linear Abrasion Resistance | Automotive, |

| Rivian Soiling and Cleanability | Automotive, |

| SAAB 1060 | Automotive, |

| SAAB 1075 | Automotive, |

| SAAB 1076 | Automotive, |

| SAAB 1077 | Automotive, |

| SAAB 1078 | Automotive, |

| SAAB 1080 | Automotive, |

| SAAB 205 | Automotive, |

| SAAB 211-1 | Automotive, |

| SAAB 211-2 | Automotive, |

| SAAB 220 | Automotive, |

| SAAB 222 | Automotive, |

| SAAB 232 | Automotive, |

| SAAB 3159 | Automotive, |

| SAAB 3770 Heat Aging | Automotive, |

| SAAB 3770 Heat Resistance | Automotive, |

| SAAB 3770-M | Automotive, |

| SAAB 3965 | Automotive, |

| SAAB 3967 | Automotive, |

| SAAB 418 | Automotive, |

| SAAB Moisture Aging | Automotive, |

| SAAB UV Aging | Automotive, |

| SAE J1351 Odor Analysis | Automotive, |

| SAE J1530 Resistance to Bearding and Fuzzing | Automotive, |

| SAE J1530 Wear Resistance | Automotive, |

| SAE J1717 Falling Ball Indentation Test | Automotive, |

| SAE J1861 Colorfastness | Automotive, |

| SAE J1885 (additional samples) | Automotive, |

| SAE J1885 Colorfastness to Light (1-5 samples) | Automotive, |

| SAE J1942 Flame Test Part 18 | Automotive, |

| SAE J1960 Colorfastness to Light (1140 kj) | Automotive, |

| SAE J200 Tear Strength | Automotive, |

| SAE J2212 Colorfastness to Light (1-5 Samples) | Automotive, |

| SAE J2412 Xenon Exposure | Automotive, |

| SAE J2412 Xenon Exposure (1-5 SAMPLES) | Automotive, |

| SAE J323 | Automotive, |

| SAE J369 Flammability | Automotive, |

| SAE J369 Flammability (As Received) | Automotive, |

| SAE J369 Flammability (Steam Aging) | Automotive, |

| SAE J530, B Wyzenbeek Wear (15,000 cycles) | Automotive, |

| SAE J681 Colorfastness | Automotive, |

| SAE J681 Colorfastness to Rubbing | Automotive, |

| SAE J860 | Automotive, |

| SAE J861 Testing Resistance to Crocking of Organic Trim Materials | Automotive, |

| SAE J883 Dimensional Stability | Automotive, |

| SAE J883 shrinkage warp and fill allowing | Automotive, |

| SAE J885 Stretch and Set of Textiles and Plastics | Automotive, |

| SAFT Heated Shear | Automotive, |

| SATRA TM 201 Water Repellency | Automotive, |

| Sim Floor Heel Rub | Automotive, |

| SNV 195651 (Modified)/CPSD-AN-00083-MTHD Odor Evaluation | Automotive, |

| Subaru Ease of Cleaning | Automotive, |

| Subaru High HumidityTest | Automotive, |

| Subaru Oil Resistance | Automotive, |

| Subaru PDTS Heat Cycle | Automotive, |

| Subaru PDTS Revision 5 Item 8 Colorfastness | Automotive, |

| Subaru PDTS, Revision 1, Item 1 High Temperature Storage Test | Automotive, |

| Subaru PDTS, Revision 1, Item 1 Low Temperature Storage Test | Automotive, |

| Subaru PDTS, Revision 5, Item 10 Wear Resistance (B) | Automotive, |

| Subaru PDTS, Revision 5, Item 8 Color Fastness | Automotive, |

| Subaru PDTS, Revision 5, Item 9 Wear Resistance (A) | Automotive, |

| Subaru TS YKB-009 Section 6 Cold Resistance | Automotive, |

| Subaru TS-YKB-008 Section 6-4-1 Item 3 Liquid Resistance | Automotive, |

| Subaru TS-YKB-008 Section 6-4-1 Item 5 Malodor Test | Automotive, |

| Subaru TS-YKB-008 Section 6-4-2 Item 6 Fogging Test | Automotive, |

| Subaru TS-YKB-008, Item 1 Tensile Strength Test | Automotive, |

| Subaru TS-YKB-008, Item 4 Adhesiveness | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, #7 Grommet Installation Area Strength Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, Item #4 Cold Resistance Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, Item 1-Temperature Cycling and Resistance Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, Item 3 Liquid Resistance Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, Item 5 Malodor Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-1, Item 6 Humidity Resistance Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-2, Item 3 Shrinkage Test | Automotive, |

| Subaru TS-YKB-008, Section 6-4-2, Item 5 Fogging Test | Automotive, |

| TESLA TM-0004T-F (Modified)/AATCC 165 Colorfastness to Crocking | Automotive, |

| TESLA TM-0044T-F Carpeting-Flat and Molded Parts | Automotive, |

| Thermal Cycle | Automotive, |

| Thermal Expansion | Automotive, |

| TL 52611 Ageing in DeIonized Water | Automotive, |

| TL 52611 DIN EN 20105 Behaviour Under Influence of Water | Automotive, |

| TL 52611 DIN EN 20105-A03 Colorfastness to Water | Automotive, |

| TL 52611 PV3905 Behavior after Low Temp Aging | Automotive, |

| TL 52611 Resistance to Heat | Automotive, |

| Toyota 4.1 Compression & Recovery | Automotive, |

| Toyota 4.10 Odor Evaluation | Automotive, |

| Toyota 4.11 Cold Flexibility | Automotive, |

| Toyota 4.13 Yellow Discoloration | Automotive, |

| Toyota 4.2 Tensile Strength | Automotive, |

| Toyota 4.3 Tensile Strength (wet) | Automotive, |

| Toyota 4.4 Tearing Strength | Automotive, |

| Toyota 4.5.1Tuft Bind of Pile Floor Coverings | Automotive, |

| Toyota 4.5.2 (wet) Tuft Bind of Pile Floor Coverings | Automotive, |

| Toyota 4.5.3 (wet and dried) Tuft Bind of Pile Floor Coverings | Automotive, |

| Toyota 4.6 Abrasion Resistance of Textile Fabrics Method | Automotive, |

| Toyota 4.7.1 Colorfastness to Rubbing | Automotive, |

| Toyota 4.7.2 Colorfastness to Light | Automotive, |

| Toyota 4.8 Aging by Moisture and Heating | Automotive, |

| Toyota Automotive Flammability | Automotive, |

| Toyota Floor Retention Properties | Automotive, |

| Toyota PPS 1001 Corrosion Resistance | Automotive, |

| Toyota PPS 1001 Corrosion Resistance Test | Automotive, |

| Toyota PPS 1005 Water Resistance of Paint Film | Automotive, |

| Toyota PPS 1006 Chemical Resistance | Automotive, |

| Toyota PPS 1007 Chem Resistance Plastic Parts Wiping | Automotive, |

| Toyota PPS 1012 Odor Evaluation | Automotive, |

| Toyota PPS 2001 Thermal Cycle Test (20 cycles) | Automotive, |

| Toyota PPS 2004 Heat Resistance | Automotive, |

| Toyota PPS 2005 Heat Aging | Automotive, |

| Toyota PPS 2006 Heat Resistance (90 degrees for 24 hours) | Automotive, |

| Toyota PPS 2008 Humidity Resistance | Automotive, |

| Toyota PPS 2012 Rubber Brittleness Temperature | Automotive, |

| Toyota PPS 2014 Weathering (1-5 samples) | Automotive, |

| Toyota PPS 2016 High Temperature Expansion | Automotive, |

| Toyota PPS 2019 Accelerated UV Light Resistance | Automotive, |

| Toyota PPS 2023 Fogging Characteristics DIN 75201A | Automotive, |

| Toyota PPS 2023 Resistance to Staining | Automotive, |

| Toyota PPS 2025 Resistance to Staining | Automotive, |

| Toyota PPS 3003 Falling Weight Test | Automotive, |

| Toyota PPS 3016 Durability | Automotive, |

| Toyota PPS 3026 Fastener Retention | Automotive, |

| Toyota PPS 3029 180 Degree Peel Adhesion | Automotive, |

| Toyota PPS 3063 Pull out Force Test | Automotive, |

| Toyota PPS 4002 Paint Adhesion Metal Badges | Automotive, |

| Toyota PPS 4003 Paint Flexibility -Bending | Automotive, |

| Toyota PPS 4008 Taber Abrasion Resistance-Plastic | Automotive, |

| Toyota PPS 4010 Paint Thickness Metal Badges | Automotive, |

| Toyota PPS 4012 Taber Resistance (<5,000 cycles) | Automotive, |

| Toyota PPS 4014 Taber Abrasion | Automotive, |

| Toyota PPS 4015 Colorfastness to Crocking | Automotive, |

| Toyota PPS 4015 Colorfastness to Laundering | Automotive, |

| Toyota PPS 4015 Colorfastness to Water | Automotive, |

| Toyota PPS 4015 Lightfastness | Automotive, |

| Toyota PPS 4015(B) Colorfastness to Water | Automotive, |

| Toyota PPS 5001 Tensile Strength & Elongation | Automotive, |

| Toyota PPS 5001 Tensile Strength & Elongation Aging/Conditioning | Automotive, |

| Toyota PPS 5003 Tear Strength | Automotive, |

| Toyota PPS 5004 Textile Flex Resistance | Automotive, |

| Toyota PPS 5006 Tuft Lock | Automotive, |

| Toyota PPS 5007 Rubber Hardness | Automotive, |

| Toyota PPS 5010 Flammability | Automotive, |

| Toyota PPS 5011 Floor Mat Bend Test | Automotive, |

| Toyota PPS 5017 Water Penetration | Automotive, |

| Toyota PPS 5018 Adhesion to Flexible Substrate | Automotive, |

| Toyota PPS 6006 Forward & Reverse Drag Test Method B | Automotive, |

| Toyota PPS 6006 Method A: Forward & Reverse Drag Test/ Method B: Rotation Drag Test | Automotive, |

| Toyota Procedure Pile Weight | Automotive, |

| Toyota TSK6712G 6.3 Bonding Performance Testing | Automotive, |

| Toyota TSL 3600G Toyota Section 7.15 (A) and (B) Colorfastness to Light | Automotive, |

| Toyota TSL3600G-1 Carpet Materials Battery | Automotive, |

| TP-0000588 Heat Endurance | Automotive, |

| TS YKB-009 Abrasion 1,000 cycles | Automotive, |

| TSL 3600G Abrasion Resistance 5,000 cycles or less w/measurement | Automotive, |

| TSL 3600g Section 7.13.1 (A) & 7.13.2 (B) Colorfastness to Crocking | Automotive, |

| TSL 3600G Toyota Section 7.15 (A) and (B) Colorfastness to Light | Automotive, |

| TSM 0500 G Flammability w/Heat Aging | Automotive, |

| TVS 344-1-11A Cycled Aging | Automotive, |

| URL 746C Resistance to Cold Impact | Automotive, |

| VDA 230-209 C Stiffness Test | Automotive, |

| VDA 270 C3 Odor Testing | Automotive, |

| VDA 270 Rotting Resistance | Automotive, |

| VDA 275 Formaldehyde | Automotive, |

| Video | Automotive, |

| Visual Inspection | Automotive, |

| Visual Ratings | Automotive, |

| Volatiles Testing | Automotive, |

| Volkswagen PV 1200 D14-343 Environmental Resistance..` | Automotive, |

| Volkswagen PV 1200 Shrinkage After Climate Change | Automotive, |

| Volkswagen PV 1303/VDA 75202 DIN EN 20105-A02 Colorfastness to Light (3 cycles) | Automotive, |

| Volkswagen PV 3929 Weathering in Dry, Hot Climate | Automotive, |

| Volkswagen PV 3930 Weathering in Moist, Hot Climate | Automotive, |

| Volkswagen PV 3934 Abrasion Test with a Heel | Automotive, |

| Volkswagen PV 3979 Wear Resistance Test | Automotive, |

| Volkswagen VW 50180 Emission Behavior | Automotive, |

| Volkswagen VW 50190 Colorimetric Evaluation | Automotive, |

| Volkswagen VW A4 Size 10 Kg Drag Test | Automotive, |

| Volkswagen VW PV 1303 Light Exposure Test (3 cycles) | Automotive, |

| Volkswagen VW PV3908 Schopper Abrasion (3 samples) | Automotive, |

| Volkswagen VW TL1010 Materials for Vehicle Interiors - Flammability of Materials Requirement | Automotive, |

| Volvo Standard: Soiling and Cleaning of Interior Plastic Surfaces | Automotive, |

| Volvo STD 1026 | Automotive, |

| Volvo STD 5031 Flammability | Automotive, |

| Warpage (Modified PFD 8145 5.4.1) | Automotive, |

| WSTDA Section 3 Destructive Straight Line Pull: Breaking Strength | Automotive, |

Ready To Get Started?

Fill out the form below and our team will get started with your next product testing.

24-HOUR QUOTE GUARANTEE

Choose a testing laboratory that turns around bids on all automotive testing services in a day or less.

EXPERTS IN AUTOMOTIVE

The PTL team has decades of experience testing automotive components and materials from bumper to bumper.

MULTI-CATEGORY TESTING

We don’t stop at automotive materials. Our lab tests carpet, wood, ceramic, chemicals, textiles, and more.

Professional Testing Laboratory LLC

All Quote Requests answered within 24 hours

714 Glenwood Place

Dalton, Georgia 30721

Phone: 706.226.3283