16 Flexible Cellular Material Tests For ASTM D3574

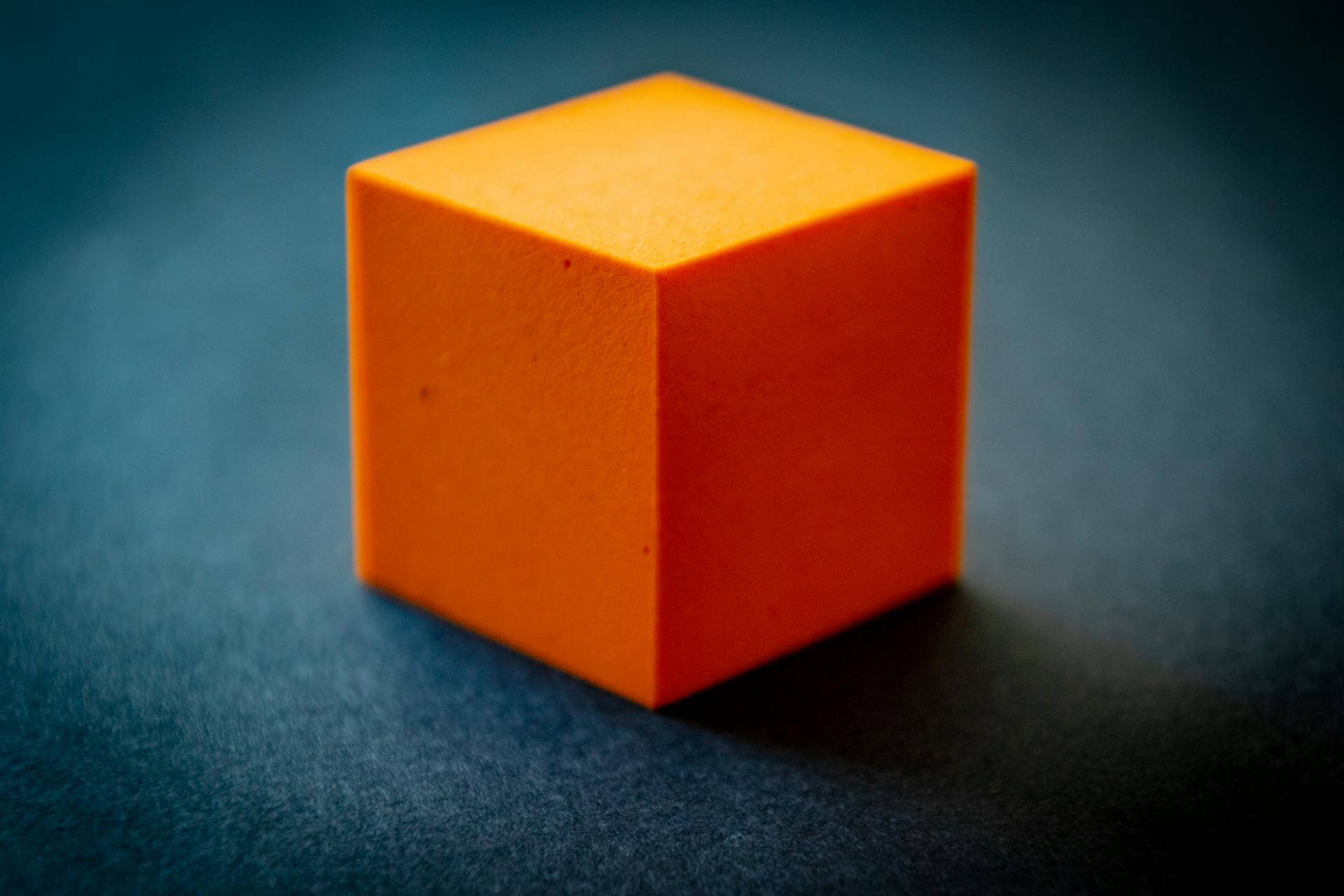

The ASTM D3574 standard – commonly referred to as the ASTM foam test – defines a series of tests used to establish the material elasticity, elongation, density, thickness, deflection, and other mechanical properties of cellular foam or rubber materials in accordance with ASTM international standards. Foams are a critical, inexpensive, and eco-friendly underlay material for floating floors and carpets, helping to provide important comfort and flexibility.

16 Flexible Cellular Material Tests for ASTM D3574

At Professional Testing Laboratory, we categorize our ASTM rubber testing methods and foam testing methods within 16 unique test variations.

- ASTM D3574 Compression Force Deflection: The CFD test assesses a foam's firmness by measuring how much force is needed to compress it to a predetermined percentage of its thickness, typically 25%, 50%, or 65%. It defines how much load or stress a given foam can withstand.

- ASTM D3574 Compression Resistance: While similar to CFD, this is a broader test that measures the foam's overall ability to resist deformation under compressive forces. It measures how much force is required to compress a foam, its durability, its and performance under load.

- ASTM D3574 Compression Set: With this test, the original thickness of the foam is measured, and then two separate plates apply force to compress the foam to a specific percentage, such as 50% or 75%, of its initial thickness. Calculations are then done to measure the permanent deflection once the plates are removed. It’s an assessment of the material's ability to recover its original thickness after a compressive load.

- ASTM D3574 Constant Deflection Compression Set: This test measures the ability of the foam to return to its original thickness after being compressed and held under a constant deflection for an extended period. It determines the degree to which the material permanently deforms (or "sets") after being compressed and held in a deformed state for a specified period of time.

- ASTM D3574 Delamination: The Delamination test evaluates the overall adhesion strength between layers in a laminated foam product but typically involves applying a force perpendicular to the plane of the layers to assess how well the layers stay together under stress. It is concerned with the tendency of the layers to separate under conditions that might cause the layers to pull apart or "delaminate" in real-world use.

- ASTM D3574 Density: This test measures the density (mass per unit volume) of a foam material, expressed in pounds per cubic foot (PCF). For example, if a foam has a density of 2 PCF, it means that one cubic foot of that foam weighs 2 pounds.

- ASTM D3574 Elongation: The Elongation test within the ASTM D3574 standard is designed to measure how much a foam material can stretch before it breaks. This test is important for assessing the flexibility and durability of flexible cellular materials.

- ASTM D3574 Indentation Force Deflection: The IFD test assesses the firmness of foam materials by measuring how much force is needed to compress the foam by a specific percentage of its original thickness. This test is crucial for determining the firmness or softness of flexible cellular materials.

- ASTM D3574 Indentation Force Deflection & Support Factor: This test offers insight into the relative firmness of a foam material when subjected to different levels of compression. Support Factor, or Sag Factor, is a measurement of the change in firmness under different levels of compression. It is calculated as the ratio of the force required to compress the foam by 65% to the force required to compress it by 25%.

- ASTM D3574 Laminate Peel: The Laminate Peel test specifically measures the force required to peel or separate two bonded layers of laminated foam or foam bonded to another material (e.g. a substrate like wood, laminate, or tile flooring).

- ASTM D3574 Resilience: This test measures the resilience of the foam to spring back to its original shape after being deformed and released. The resiliency of flexible cellular materials like foams is measured using a steel ball rebound test.

- ASTM D3574 Static Force Loss @ Constant Deflection: This test measures the loss of force or load-bearing capacity of flexible cellular materials after a load is applied. Officially, this measure is defined as the indentation force deflection (IFD).

- ASTM D3574 Tensile Strength: The Tensile Strength test measures the force required to pull a foam sample until it ruptures. Samples of foam are cut in what is commonly referred to as a “dog-bone” sample. Each end of the sample is held by grips – typically by an Instron machine. Tensile strength is a measurement of the actual force (lbs) required before the foam “dogbone” sample breaks or tears.

- ASTM D3574 Test H Ball Drop Resiliency: Rebound resilience is measured by dropping a steel ball onto a foam specimen and measuring the height of the rebound. The ASTM D3574 test H is identical to ISO 8307.

- ASTM D3574 Thickness: This refers to the measurement of the thickness of flexible cellular materials, such as urethane foams, as part of the ASTM D3574 standard. Thickness measurement is often needed as a baseline test to determine the exact thickness of the foam sample before it undergoes any further testing.

- ASTM D3574 Weight: The test measures the foam’s mass on a scale for comparison with its volume as a way to establish density. The specimen is cut to a specified size and shape — usually a rectangular or cubic piece — and weighed using a precise balance to determine its mass.

Professional Testing Laboratory: Your Flooring Material Testing Partner

Professional Testing Laboratory is a PJLA and NVLAP-accredited third-party testing facility committed to providing its industrial and commercial customers with accurate test data across ASTM standards and other critical test standards (ANSI, ISO, and more). Renowned for our repeatability of process, exceptional 30,000 square-foot test facility, cutting-edge test equipment, and committed test team, we are often called upon to perform customized test procedures for customers in flooring, textile & fabrics, vacuum & cleaning, aerospace, automotive, consumer products, and adhesive & tapes industries.

If you need foam testing done according to ASTM D3574 by a testing partner you can trust, get in touch for a quote within 24 hours.